Courtesy of Frodsham

The full story of the Charles Frodsham Double Impulse Chronometer

The first new English watch in nearly half a century has been in development for 25 years. One man has been following the story since the early years; now he charts the various paths that led to the first wristwatch ever to bear the name of Charles Frodsham

There hasn't been a mechanical wristwatch made in England since Smith’s closed its factory half a century ago (geographical pedants know that the Isle of Man is not in England) so when Charles Frodsham introduced its new Double Impulse Chronometer watch in 2018, it marked the return of watchmaking to the country which played the most important part in its development.

I have known the guys behind Frodsham for over a quarter-century, but that is a mere blink of an eye compared to the 184 years since Charles Frodsham founded the firm and 175 years since they became England’s premier maker of chronometers after purchasing the firm of John Roger Arnold. The Victorian era was one of consolidation among the great English watch and clock makers and by the end of the 19th century, there were just two great firms trading in London – Dent and Frodsham. Dent built the clock in the tower of Pugin’s new Houses of Parliament, while Frodsham built chronometers for the Royal Navy and regulators for astronomical observatories around the world.

Through two world wars (including being bombed out of their premises in 1941) and the austerity following them, the firm continued production, but in the mid 1990s it was purchased by Philip Whyte, one of London’s leading dealers in marine chronometers and precision timekeeping.

He brought in as a partner Richard Stenning, who had previously worked for seven years in the watch and clock department at Sotheby’s. Prior to this he had studied horology at Hackney, under Peter Roberts. By then, the Frodsham business specialised in buying and selling timepieces from their premises in St James and servicing & repairing them from their workshop in Heathfield, Sussex.

The firm came swiftly to the conclusion that they needed to get back into manufacturing, but whether to make chronometer desk clocks or a watch?

Although Frodsham’s history had been based on chronometer clocks and precision regulators, by the end of the 19th century it had been regularly winning awards for its watches, one of its tourbillons achieving the highest marks ever attained by an English watch at Kew observatory, in 1906. So, it was an easy decision to go ahead with a watch.

In keeping with the firm’s long history of chronometer making, their first thoughts were to produce a wristwatch using the detent escapement as used in most marine chronometers. And therein lay a problem; chronometers are almost always held in a box, kept in one position and often fitted with gimbals to ensure that the timepiece stayed flat, no matter how much the ship might move.

Obviously, a wristwatch needs to operate in any position and to be able to accept the occasional shock. Knowing all this, their first attempt at an in-house movement featured a detent escapement, fitted to that ubiquitous horological workhorse, the Unitas 6497. The problem with the detent escapement, as distinct from a lever escapement is that it is impulsed only in one direction and is incredibly susceptible to shock. Frodsham got it to run, but random movements of the wrist or external impacts could cause the escapement to either gallop or to set. Despite these problems (or perhaps because of them) the production of a detent escapement wristwatch became something of a watchmakers’ holy grail.

Breguet filed a patent for one in 2003, while Christophe Claret unveiled his Maestoso watch in 2014, but the first company to actually introduce a detent wristwatch was Urban Jurgensen in 2011. I was present at the launch of the watch and listened as Jean-Francois Mojon & Kari Voutilainen explained the procedures and modifications needed to make this delicate mechanism work in such a hostile environment. They told how the project had begun when the firm was under the ownership of Peter Baumberger and that the initial research had been done by the firm’s technical director, Derek Pratt. Neither of whom, unfortunately, lived to see the launch of the Urban Jurgensen detent watch.

But Pratt, who was one of the greatest watchmakers of the 20th century, although one of the least known, was engaged on a major personal project along with his work for Urban Jurgensen – he was building a perfect replica of Harrison’s H4. This necessitated frequent visits from his workshop in Switzerland to Greenwich to examine the original, and while in London he would often pop into Frodsham’s and chat about the problems and progress that they were both experiencing with the detent. On one occasion in May 2004, he showed them his Double Wheel Escapement pocket Tourbillon and suggested that this escapement might be a solution.

There were, at this time, including Pratt’s watch only eight Double Wheel Escapement pocket watches in the entire world and nobody had yet shrunk the mechanism enough to fit into a wristwatch. In fact, its developer George Daniels had always said that it would be a huge challenge to miniaturise the escapement to fit into a wristwatch, but materials, tools & technology had all progressed since and the Frodsham team decided to try.

Once again using the reliable Unitas base, they produced their first proof-of-concept movement in 2005; it was cased up and then tested for almost 3 years while a brand new, in-house English movement using the new escapement was designed on the metaphorical blank sheet of paper. Three prototypes of this new movement were built; the first one, uncased, was ready in time to be displayed at the 150th anniversary of the British Horological Institute in June 2008.

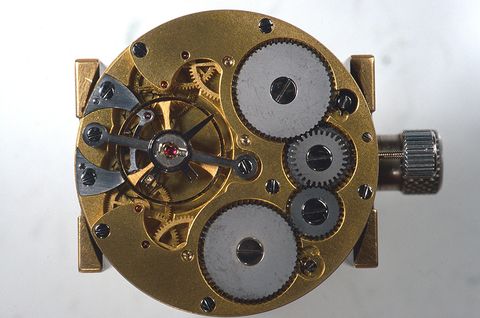

Then began the hard work of developing the prototypes into production ready versions; the Unitas ‘mules’ had been built with no thought given to aesthetics, the only target being to get the thing to work. But now great thought and care was given to the appearance of the movement and the challenge became to retain the aesthetics without compromising the mechanical integrity. The decision was made that mechanics would come first and that aesthetics would always play second fiddle, but the Frodsham team had cut their teeth (in both senses of the phrase) on vintage movements. So they were inspired by the aesthetics of the vintage Frodshams to produce a movement which not only worked flawlessly, but also looked perfect.

Early on in the development process, it was realised that individual components could rarely be designed in isolation. While a wheel or bridge might look better if it was five per cent slimmer or had a different finish, once fitted to the movement it could look wrong next to its fellow components, so the decision was made never to work on individual components alone – visual changes and modifications to parts were done in context with their surrounding components.

The balance between mechanics and aesthetics is best shown in the wide range of materials used in the watch – titanium for the detent, 18ct rose gold for the train wheels, black polished steel for the balance bridge, tungsten carbide for the balance timing weights and a special three metal copper alloy (copper/nickel/tin) for the balance wheel.

The prototypes were now fitted in simple steel cases and worn regularly, one by Philip Whyte who repaired his car, mowed the lawn and commuted daily into London wearing it, while another member of the team regularly wore his on long bike rides. They were determined that the new movement would be reliable.

One of the three prototypes was left exactly as it was when produced, for comparison with the other two which underwent a huge number of iterations. Initially, the escapement geometries were made to George Daniels’ original designs for a pocket watch, but subtle changes were incorporated into the wristwatch version, for example a change in the roller diameter and the position of the secondary locking jewels. They experimented with different materials for the escape wheels; many were tried and rejected before they finally decided on titanium. The dynamic workings of the escapement are very different to any theoretical modelling. The variables measured included wear, lubricity, how quickly the escape wheel released, how quickly it accelerated, and its terminal velocity at the point of impulse.

One of the most beautiful aspects of the movement is the asymmetric three-armed balance bridge, which combines exceptional stability with an almost unhindered view of the balance assembly. It was not always this way. Over the development period, the bridge was tried with two arms and also as a simple balance cock. It takes an astonishing 11 hours of hand polishing to achieve the desired finish.

Their search for the correct method and materials is best exemplified in the use of zirconium oxide on the dial. While the prototypes used conventional silver dials with engraved and filled numbers, for the production watches they wanted something similar to enamel without its drawbacks – the propensity to crack and the ‘dipping’ at any holes in the dial (centre and subsidiary second posts or around applied numerals).

Used in ‘gauge blocks’ – perfectly flat and parallel surfaces – to calibrate precision engineering tools, zirconium oxide ceramic was available in samples no thinner than 1mm thick, so it was lapped down to only 45 per cent of its former height. The resulting perfectly flat surface was too reflective, so it was bombarded with a micro-grained aluminium oxide to provide a finish which is neither too matt nor too glossy.

When it came to printing the dial, conventional methods were discarded in favour of methods hitherto only used in the eyepieces of telescopic sights & microscopes. Using a variant of physical vapour deposition, it is possible to produce consistent lines less than half the width of a human hair. Because the material deposited onto the dial is a metallic oxide, it does not degrade in any way and is much more permanent than any other dial printing method yet used anywhere else.

I mentioned earlier that Derek Pratt had been working on a perfect replica of Harrison’s H4 when he was discussing detent wristwatches with Frodsham’s; unfortunately, a recurrence of prostate cancer prevented him from finishing the project and Frodham’s agreed to complete it in time for the 2014 tercentenary of the Longitude Act. Concentrating on this project, and on a replica of H3 for the same event, caused work on the wristwatch to slip behind. But skills learned during the production of the H4 replica proved their worth, particularly in such fields as machining the detent, which weighs a microscopic 0.0037 of a gram.

Funded totally from internal funds with no outside investors, the Double Impulse Chronometer has taken what seems to be an inordinate length of time to come to market; but it seems more reasonable when you realise that this was so much more than just designing and building a watch. It was a project where experimentation, trial and error and the endless search for perfection each played a role, and the wait has proved to be well worth it.

No comments:

Post a Comment